Simulations of ultrasonic inspections

With CIVA simulations, we optimize ultrasonic testing of welds and metal structures. Precise analyses, validated results, and practical insights ensure quality in nuclear, mechanical, and civil engineering.

Contact

Dr. Daniel Algernon

Head of the NDT laboratory

Telefon: +41 44 877 62 59

E-Mail: daniel.algernon@svti.ch

We use the CIVA simulation software to reproduce and analyze ultrasonic testing of metal structures – particularly weld inspections – in safety-critical sectors such as nuclear, mechanical, and civil engineering.

Our expertise in non-destructive testing (NDT) covers both conventional ultrasonic testing (UT) and advanced methods such as Phased Array UT (PAUT) and the Total Focusing Method (TFM). This provides engineers and decision-makers with a reliable basis to develop testing strategies, validate procedures, and optimize quality assurance.

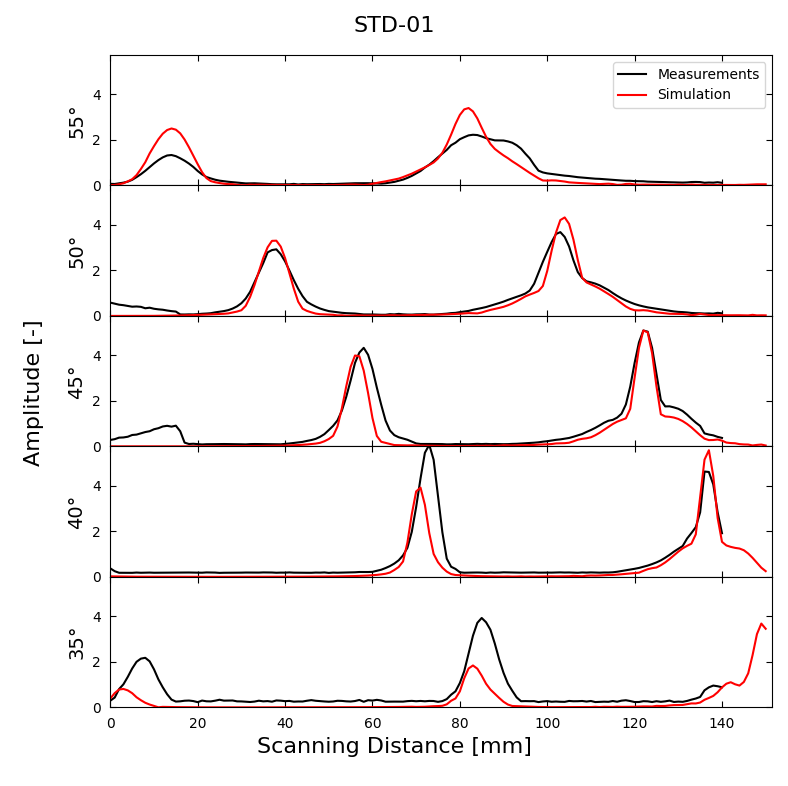

A key advantage of our approach lies in the combination of simulation and practice: we compare simulation results with calibration block measurements containing known flaws. This ensures accuracy, transparency, and verifiability. Subsequent data analysis and post-processing bridge the gap between test design and test reality, delivering actionable insights for industrial applications.

Whether in weld inspection, metal material testing, or quality assurance of complex components, CIVA simulations support companies in implementing safe, efficient, and standards-compliant testing processes.

Contact us today to learn more about the use of CIVA simulations in ultrasonic testing or to request tailored consulting for your project.